Comparing Diamond Metal Cutting Wheels and Bonded Cutting Wheels

When it comes to metalworking, cutting discs are essential. The right cutting disc can make all the difference in efficiency, precision, and safety. Two common options are diamond metal cutting wheels and bonded cutting wheels. If you're wondering which one to choose, this guide will cover their features, benefits, drawbacks, and ideal use cases. Let's dive into the details and discover which cutting wheel might be the best for your project!

Table of Contents

- Introduction

- Understanding Cutting Discs

- Types of Cutting Wheels

- 3.1 Diamond Cutting Wheels

- 3.2 Bonded Cutting Wheels

- Key Factors for Choosing a Cutting Wheel

- Diamond Metal Cutting Wheels: An Overview

- 5.1 How They Work

- 5.2 Best Use Cases

- Bonded Cutting Wheels: A Closer Look

- 6.1 How They Work

- 6.2 Best Use Cases

- Comparing Diamond and Bonded Wheels: Key Differences

- 7.1 Material and Durability

- 7.2 Cutting Speed

- 7.3 Cost-Effectiveness

- Safety Considerations

- Environmental Impact

- Which Wheel Should You Choose?

- Conclusion

- FAQs

- Introduction

Cutting through metal can be challenging without the right tools. With a vast range of cut off wheels and cutting discs on the market, understanding what each type offers can help you make a more informed decision. This comparison of diamond and bonded cutting wheels will help you choose the ideal tool for your project, saving time and reducing wear on your equipment.

- Understanding Cutting Discs

A cutting disc, or cut off wheel, is a thin, circular tool designed to cut through metal, steel, or other materials. Each type of disc is designed with different materials, shapes, and specifications to meet various cutting needs.

- Types of Cutting Wheels

There are two primary types of metal cutting wheels in the market: diamond metal cutting wheels and bonded cutting wheels. Each type has its strengths and weaknesses depending on the project requirements.

3.1 Diamond Cutting Wheels

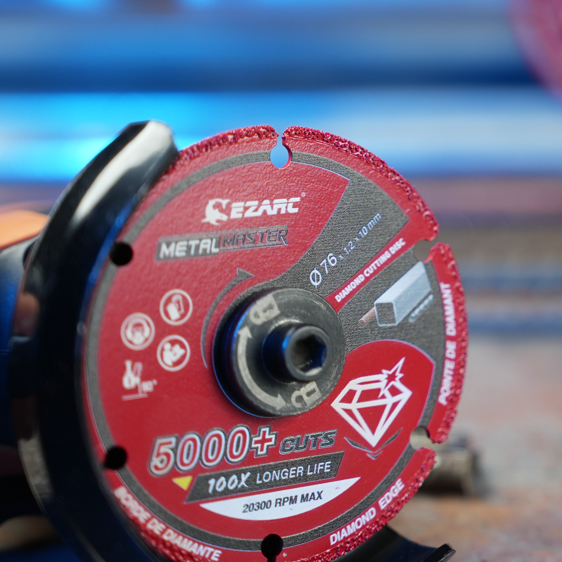

Diamond cutting wheels are known for their durability and precision. Coated with industrial diamonds, these wheels are effective for heavy-duty cutting jobs, lasting longer and performing consistently.

3.2 Bonded Cutting Wheels

Bonded wheels are the traditional choice and are made of abrasive grains bonded together with resin. They’re often used for a wide range of general metal cutting applications and offer versatility at a lower cost.

- Key Factors for Choosing a Cutting Wheel

When choosing a cutting disc, factors like the type of material, thickness of the disc, cutting speed, and durability are essential. Each factor can significantly affect the wheel’s performance and longevity, making it essential to choose carefully based on the job requirements.

- Diamond Metal Cutting Wheels: An Overview

Diamond metal cutting wheels are built to perform on heavy-duty applications, with industrial diamonds embedded on the surface.

5.1 How They Work

The diamond particles are bonded to the disc's edge, allowing it to cut through metals efficiently without breaking down as quickly as bonded wheels. The diamond abrasives remain sharp, making these wheels ideal for precision cutting.

5.2 Best Use Cases

Diamond wheels are suitable for industrial applications and can handle harder metals, including stainless steel. They are perfect for repetitive cutting and perform well under high-stress environments.

- Bonded Cutting Wheels: A Closer Look

Bonded cutting wheels use abrasive grains like aluminum oxide, held together with a resin matrix. They come in various thicknesses and grit levels.

6.1 How They Work

The grains wear down during cutting, gradually exposing new, sharp grains. This process gives bonded wheels a high cutting speed initially, but they wear down faster than diamond wheels.

6.2 Best Use Cases

Bonded cutting wheels are best suited for general-purpose metal cutting and are often used in fabrication and automotive industries. They are affordable and work well on softer metals.

- Comparing Diamond and Bonded Wheels: Key Differences

7.1 Material and Durability

Diamond cutting wheels are highly durable due to the toughness of industrial diamonds, while bonded wheels are more prone to breaking and wearing down. Diamond wheels excel in durability, making them ideal for high-frequency cutting.

7.2 Cutting Speed

Bonded wheels typically have an initial faster cut rate since they’re designed to grind down quickly. However, they lose cutting power as they wear down, whereas diamond wheels maintain a consistent speed over time.

7.3 Cost-Effectiveness

Diamond wheels come with a higher initial cost, but their durability and extended lifespan often result in a lower cost over time. Bonded wheels are more affordable upfront but may need frequent replacement in demanding applications.

- Safety Considerations

Both diamond and bonded wheels require proper safety measures. Bonded wheels are more prone to shattering, posing risks during high-speed cutting. Diamond wheels, though less likely to shatter, can create sparks and heat, requiring eye protection and gloves.

- Environmental Impact

Diamond wheels tend to last longer and produce less waste over time, making them a more eco-friendly choice. Bonded wheels, while cheaper, generate more frequent waste due to shorter lifespans.

- Which Wheel Should You Choose?

The choice between diamond and bonded wheels largely depends on your project needs:

- For heavy-duty, high-precision, and repeated metal cutting, diamond wheels provide better performance and longevity.

- For general-purpose, lower-cost cutting, bonded wheels are an affordable and reliable option.

- Conclusion

In summary, both diamond metal cutting wheels and bonded cutting wheels have their places in metalworking. Diamond wheels stand out in heavy-duty applications where durability and precision are essential. Bonded wheels, on the other hand, offer a budget-friendly, versatile solution for general metal cutting tasks. Understanding the unique strengths of each can help you choose the best cut off wheels for your needs, ensuring effective and efficient results.

- FAQs

Q1: Can I use a diamond cutting wheel on any type of metal?

Yes, diamond cutting wheels are versatile and can cut through a wide range of metals, including harder materials like stainless steel.

Q2: How long do diamond metal cutting wheels last?

Diamond wheels are designed for durability and can last significantly longer than bonded wheels, making them a cost-effective choice for high-frequency cutting.

Q3: Are bonded cutting wheels more dangerous than diamond wheels?

Bonded wheels can be more prone to shattering, so always wear appropriate safety gear. Diamond wheels are generally safer as they are less likely to break.

Q4: What’s the main advantage of bonded cutting wheels?

Bonded wheels are affordable, making them ideal for those on a budget or for projects requiring general-purpose metal cutting.

Q5: Do diamond cutting wheels require special storage?

It’s best to store diamond wheels in a dry place, away from moisture, to maintain their longevity and performance. Bonded wheels also benefit from a dry, stable storage environment.

Choosing the right cutting wheel is crucial, whether you’re a DIY enthusiast or a professional fabricator. Make your choice wisely, and your projects will be safer, smoother, and more efficient.

Oscillating Multi-Tool Blades

Oscillating Multi-Tool Blades

Reciprocating Saw Blades

Reciprocating Saw Blades

Cutting & Grinding

Cutting & Grinding

Hole Saw

Hole Saw

Drilling

Drilling

Sanding & Polishing

Sanding & Polishing

Hand Tools

Hand Tools

BEST SELLERS

BEST SELLERS

NEW ARRIVALS

NEW ARRIVALS

Clearance Sale

Clearance Sale

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.