If you've ever struggled with drilling clean, precise holes in tough materials, you're not alone. The standard hole saw can only take you so far before it starts to wear out or, worse, fails entirely. That’s where carbide hole saws step in, offering durability, speed, and precision that can handle even the most demanding tasks. Whether you're a seasoned professional or a DIY enthusiast, understanding how to use carbide hole saws effectively can make a world of difference in your projects.

Table of Contents

- What Is a Carbide Hole Saw?

-

Why Use a Carbide Hole Saw?

- Benefits Over Traditional Hole Saws

-

How Carbide Hole Saws Are Constructed

- The Cutting Edge: Tungsten Carbide

- The Body: Reinforced Steel

-

Materials You Can Cut with Carbide Hole Saws

- Metal

- Ceramic and Tile

- Wood and Composites

-

Step-by-Step Guide to Using a Carbide Hole Saw

- Step 1: Select the Right Hole Saw

- Step 2: Secure the Workpiece

- Step 3: Attach the Hole Saw to the Drill

- Step 4: Drill the Hole

-

Best Practices for Smooth, Clean Cuts

- Use Proper Speed and Pressure

- Cool the Saw with Lubricant

-

Common Mistakes and How to Avoid Them

- Forcing the Saw

- Skipping Pilot Holes

-

Safety Tips for Using Carbide Hole Saws

- Wear Eye and Hand Protection

- Secure Your Work Area

-

Maintenance and Longevity

- Cleaning and Storing

- Sharpening or Replacing Teeth

-

Top Brands of Carbide Hole Saws

- Bosch

- Lenox

- Milwaukee

-

Applications of Carbide Hole Saws

- Construction and Renovation

- Electrical and Plumbing Work

- Conclusion

- Frequently Asked Questions

What Is a Carbide Hole Saw?

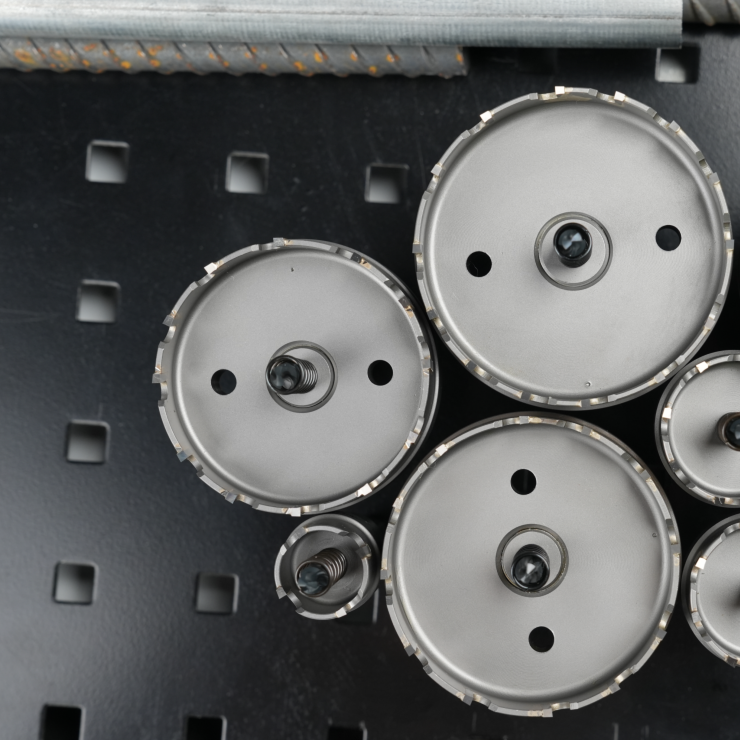

A carbide hole saw is a circular cutting tool designed to drill holes into hard materials like metal, tile, and stone. Unlike traditional hole saws that use steel teeth, carbide hole saws are tipped with tungsten carbide, one of the hardest materials known to man. This makes them incredibly tough and long-lasting, capable of cutting through materials that would dull a regular saw in no time.

Why Use a Carbide Hole Saw?

Benefits Over Traditional Hole Saws

Carbide hole saws offer several advantages:

- Increased Durability:Thanks to their tungsten carbide tips, these saws can handle tougher materials and last significantly longer.

- Faster Cutting:They maintain their sharpness better than steel, allowing for quicker, more efficient cuts.

- Cleaner Holes:Carbide hole saws reduce chipping and cracking, leaving you with smooth, professional-looking holes.

How Carbide Hole Saws Are Constructed

The Cutting Edge: Tungsten Carbide

The cutting edge of a carbide hole saw is embedded with tungsten carbide teeth, which are heat-resistant and capable of retaining their sharpness even after repeated use.

The Body: Reinforced Steel

The body of the saw is typically made from reinforced steel, providing the necessary strength to withstand the pressure of drilling into hard surfaces.

Materials You Can Cut with Carbide Hole Saws

One of the most impressive features of carbide hole saws is their versatility. They can cut through:

1. Metal

From stainless steel to cast iron, carbide hole saws make short work of tough metals.

2. Ceramic and Tile

Need to install a new sink or shower fixture? Carbide hole saws can handle delicate yet hard surfaces like ceramic and porcelain without cracking.

3. Wood and Composites

While they excel at cutting metal and tile, carbide hole saws are also suitable for wood, especially if you're dealing with dense hardwoods or composites.

Step-by-Step Guide to Using a Carbide Hole Saw

Step 1: Select the Right Hole Saw

Choose a carbide hole saw that matches the size of the hole you need and is designed for the material you’re working with.

Step 2: Secure the Workpiece

Make sure your material is clamped down securely to prevent movement during drilling.

Step 3: Attach the Hole Saw to the Drill

Connect the hole saw to a power drill using an arbor and ensure it's tightly secured.

Step 4: Drill the Hole

Start at a low speed to avoid wandering, then gradually increase speed as the teeth bite into the material.

Best Practices for Smooth, Clean Cuts

Use Proper Speed and Pressure

Avoid applying too much pressure. Let the saw do the work and adjust the drill speed based on the material.

Cool the Saw with Lubricant

When cutting metal, use cutting oil or another lubricant to reduce heat and prolong the life of the saw.

Common Mistakes and How to Avoid Them

Forcing the Saw

Pushing too hard can cause the saw to overheat or wear out prematurely. Instead, apply steady, consistent pressure.

Skipping Pilot Holes

Skipping a pilot hole can lead to wandering, especially on hard surfaces. Always drill a pilot hole first for accuracy.

Safety Tips for Using Carbide Hole Saws

- Wear Eye and Hand Protection:Flying debris can be dangerous, so goggles and gloves are a must.

- Secure Your Work Area:Make sure your workspace is stable and free from obstructions.

Maintenance and Longevity

Cleaning and Storing

After each use, clean the saw to remove debris and store it in a dry place to prevent rust.

Sharpening or Replacing Teeth

Over time, the teeth may dull. While carbide teeth can be sharpened, it’s often more practical to replace the hole saw if it becomes too worn.

Top Brands of Carbide Hole Saws

- Bosch:Known for precision and durability.

- Lenox:Offers a wide range of sizes and excellent performance.

- Milwaukee:A favorite among professionals for heavy-duty applications.

Applications of Carbide Hole Saws

Construction and Renovation

Perfect for cutting holes in metal beams, tile walls, and concrete floors.

Electrical and Plumbing Work

Essential for drilling clean holes for pipes, conduits, and wiring.

Conclusion

A carbide hole saw is a versatile, durable tool that can handle some of the toughest materials out there. Whether you're working with metal, tile, or hardwood, this tool offers precision, speed, and reliability. By choosing the right saw, using proper techniques, and maintaining it well, you can ensure clean, professional results every time.

Frequently Asked Questions

1. Can carbide hole saws cut through stainless steel?

Yes, carbide hole saws are ideal for cutting through stainless steel, especially when using cutting oil to reduce heat.

2. How long do carbide hole saws last?

With proper care and maintenance, a high-quality carbide hole saw can last for years, even with frequent use.

3. Can I use a carbide hole saw on a cordless drill?

Yes, as long as your cordless drill has sufficient power for the material you're cutting.

4. Do I need lubricant for cutting wood?

While lubricant isn’t necessary for wood, it can help reduce heat and extend the saw’s lifespan when cutting dense materials.

5. Are carbide hole saws worth the investment?

Absolutely! Their durability, versatility, and ability to cut through tough materials make them a cost-effective choice in the long run.

Oscillating Multi-Tool Blades

Oscillating Multi-Tool Blades

Reciprocating Saw Blades

Reciprocating Saw Blades

Cutting & Grinding

Cutting & Grinding

Hole Saw

Hole Saw

Drilling

Drilling

Sanding & Polishing

Sanding & Polishing

Hand Tools

Hand Tools

BEST SELLERS

BEST SELLERS

NEW ARRIVALS

NEW ARRIVALS

Clearance Sale

Clearance Sale

Laisser un commentaire

Ce site est protégé par hCaptcha, et la Politique de confidentialité et les Conditions de service de hCaptcha s’appliquent.