When it comes to shaping, grinding, or finishing metal surfaces, a simple hand file won’t always cut it (pun intended). That’s where metal rotary files—also known as carbide burrs or die grinder bits—come into play. These versatile tools are essential in metalworking, offering precision, speed, and efficiency in tasks that would otherwise require hours of manual labor. Whether you're a professional fabricator or a hobbyist looking to elevate your craftsmanship, understanding how to use metal rotary files can significantly improve your results.

Table of Contents

- What Are Metal Rotary Files?

-

Why Use Metal Rotary Files?

- Key Advantages

-

Types of Metal Rotary Files

- Based on Material

- Based on Shape

-

Common Applications of Metal Rotary Files

- Deburring

- Shaping and Sculpting

- Surface Finishing

-

Choosing the Right Rotary File for Your Project

- Material Compatibility

- Shape Selection

-

How to Use Metal Rotary Files: A Step-by-Step Guide

- Step 1: Select the Appropriate File

- Step 2: Secure the Workpiece

- Step 3: Attach the File to the Rotary Tool

- Step 4: Begin Filing

-

Best Practices for Optimal Results

- Use Steady, Controlled Movements

- Avoid Overheating the Tool

-

Common Mistakes and How to Avoid Them

- Applying Too Much Pressure

- Choosing the Wrong File

-

Safety Tips for Using Metal Rotary Files

- Protective Gear

- Work Area Safety

-

Maintenance and Longevity

- Cleaning After Use

- Proper Storage

-

Top Brands of Metal Rotary Files

- Dremel

- Tungsten Tools USA

- Astro Pneumatic

- Conclusion

- Frequently Asked Questions

What Are Metal Rotary Files?

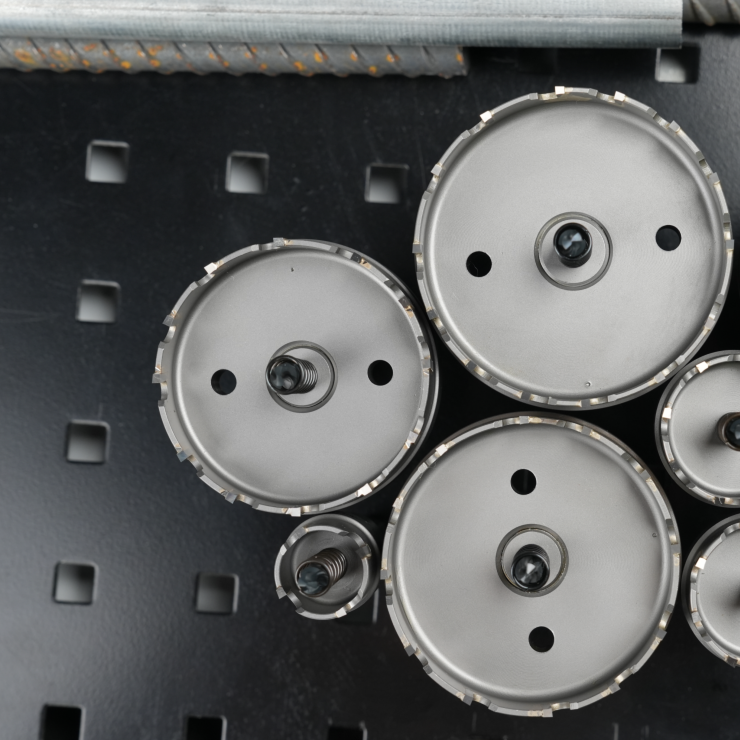

Metal rotary files are cylindrical or conical cutting tools made from high-speed steel (HSS) or tungsten carbide. They are designed to be attached to a rotary tool, such as a die grinder or a Dremel, and are used for shaping, grinding, and finishing metal surfaces with precision.

Unlike traditional hand files, rotary files spin at high speeds, allowing you to remove material quickly and efficiently. Think of them as the power tool equivalent of a sculptor's chisel—precise, versatile, and essential.

Why Use Metal Rotary Files?

Key Advantages

- Precision:Rotary files offer unparalleled control, allowing for intricate detailing and fine finishing.

- Speed:These tools can remove material much faster than traditional hand files, making them ideal for large projects.

- Versatility:From deburring rough edges to shaping custom components, rotary files can handle a wide range of tasks.

Types of Metal Rotary Files

Based on Material

- Tungsten Carbide Rotary Files:Known for their durability and ability to cut through tough metals like stainless steel and cast iron.

- High-Speed Steel (HSS) Files:More affordable but less durable than carbide, making them suitable for softer metals like aluminum and brass.

Based on Shape

- Cylinder:Ideal for flat surfaces and right-angle corners.

- Ball:Perfect for concave surfaces and rounded edges.

- Cone:Great for narrow spaces and precision work.

- Flame:Designed for intricate detailing and sculpting.

Common Applications of Metal Rotary Files

1. Deburring

Removing sharp edges and burrs from cut metal is essential for safety and aesthetics. Rotary files make quick work of these imperfections.

2. Shaping and Sculpting

Creating custom shapes or fine details in metalwork is much easier with the precision of a rotary file.

3. Surface Finishing

Smooth out welds, polish surfaces, or prepare metal for painting or coating with a rotary file.

Choosing the Right Rotary File for Your Project

Material Compatibility

Ensure the rotary file you choose is compatible with the material you're working on. Tungsten carbide files are best for hard metals, while HSS files work well on softer metals.

Shape Selection

The shape of the rotary file should match the contours of the surface you're working on. For example, a cylindrical file is ideal for flat surfaces, while a ball-shaped file works better on curved surfaces.

How to Use Metal Rotary Files: A Step-by-Step Guide

Step 1: Select the Appropriate File

Choose a file that suits both the material and the task at hand.

Step 2: Secure the Workpiece

Clamp down the metal piece to prevent movement during filing.

Step 3: Attach the File to the Rotary Tool

Secure the rotary file in the tool's chuck, ensuring it's tightly fastened.

Step 4: Begin Filing

Turn on the rotary tool and gently guide the file along the surface, applying light pressure.

Best Practices for Optimal Results

Use Steady, Controlled Movements

Avoid rushing. Move the file steadily across the surface for a smooth, even finish.

Avoid Overheating the Tool

High-speed filing generates heat. Take breaks or use a lubricant to prevent overheating.

Common Mistakes and How to Avoid Them

Applying Too Much Pressure

Let the file do the work. Excessive pressure can damage both the file and the workpiece.

Choosing the Wrong File

Using an inappropriate file shape or material can result in poor performance and damage to the tool.

Safety Tips for Using Metal Rotary Files

- Wear Protective Gear:Always wear safety goggles and gloves to protect against flying debris and heat.

- Ensure Work Area Safety:Keep your workspace clean and free of obstructions.

Maintenance and Longevity

Cleaning After Use

Remove debris and metal shavings from the file using a brush or compressed air.

Proper Storage

Store your rotary files in a dry, secure place to prevent rust and damage.

Top Brands of Metal Rotary Files

- Dremel:Known for precision and versatility.

- Tungsten Tools USA:Offers durable, high-performance rotary files.

- Astro Pneumatic:Provides a wide range of professional-grade tools.

Conclusion

Metal rotary files are an invaluable tool for anyone working with metal, offering precision, speed, and versatility. By choosing the right file, using proper techniques, and maintaining your tools, you can achieve professional-grade results in your projects. Whether you're deburring, shaping, or finishing, a rotary file can help you work smarter, not harder.

Frequently Asked Questions

1. Can metal rotary files be used on wood?

Yes, but they are primarily designed for metal. Use a lower speed to avoid burning the wood.

2. How long do rotary files last?

With proper care, high-quality rotary files can last for years, even with frequent use.

3. Do I need a special rotary tool to use these files?

No, most rotary files are compatible with standard rotary tools and die grinders.

4. Can I sharpen a dull rotary file?

While possible, it's often more practical to replace a dull file, especially if it's tungsten carbide.

5. Are rotary files worth the investment?

Absolutely! Their precision, speed, and versatility make them a cost-effective addition to any metalworking toolkit.

Oscillating Multi-Tool Blades

Oscillating Multi-Tool Blades

Reciprocating Saw Blades

Reciprocating Saw Blades

Cutting & Grinding

Cutting & Grinding

Hole Saw

Hole Saw

Drilling

Drilling

Sanding & Polishing

Sanding & Polishing

Hand Tools

Hand Tools

BEST SELLERS

BEST SELLERS

NEW ARRIVALS

NEW ARRIVALS

Laisser un commentaire

Ce site est protégé par hCaptcha, et la Politique de confidentialité et les Conditions de service de hCaptcha s’appliquent.